What are Retaining Walls, Their Types and History?

Every building built from past to present is located under natural ground and conditions. Structures that are in balance with the moving natural ground have been able to preserve themselves until today.

What is a Retaining Wall?

Retaining walls; They are rigid structures built to ensure that the soil and the structures on it stand upright or to prevent them from collapsing, so that an excavation or a filling area to be made with an existing area does not slide.

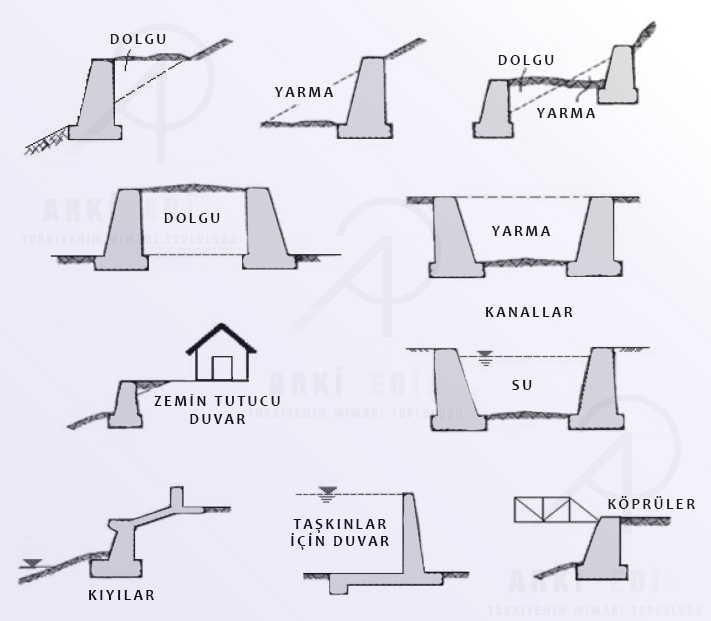

What is a Retaining Wall Used For?

- To keep the ground at a steeper angle than the natural slope in order to benefit from the land in sloping lands,

- To prevent floors that are likely to collapse from sliding,

- Creating building basement walls,

- To prevent coastal erosion or protect from floods,

- Channels and inclusions

- To act as side piers on bridges,

- In deep excavations,

- To use it when making slope adjustments on the road route,

- Using stabilized and coal storage,

- On roads requiring filling and splitting,

- It is used on hillside roads.

Retaining Walls from Past to Present

When we consider retaining walls chronologically from past to present, it is possible to classify them according to the function of the structure and material types.

Although retaining walls were made from simple systems in the past with the help of different materials, today they have gained a place in a wide range of areas, ranging from complex systems.

If we list them from old to new;

Classic Retaining Walls; Adobe wall, masonry wall, stone wall, concrete wall, reinforced concrete wall, buttress wall, pile walls, soil nailed walls, pre-stressed and anchored walls

New Technological Retaining Walls; Retaining wall applications can also be made with flexible systems such as Terramesh System, Green Terramesh (green wall) System, Earthenware Wall, gravity type retaining wall and Gabion.

Relationship between Soil and Retaining Wall

Retaining walls must be in balance. If we look at the ground and bearing loads, which are one of the most basic factors, it works according to ground pressure; They are distinguished by two limit values.

These are the “active ground pressure” that occurs when the background ground collapses when the wall changes its position slightly from the ground fill to the outer surface, and the “passive ground pressure” that occurs when the background ground swells when the wall moves towards the fill.

If neither situation occurs, it is called “quiet state”. Classical studies on the effects of active and passive pressures on the lateral ground on the wall were carried out by Coulomb and Rankine between 1776 and 1857. The first studies on the calculation of dynamic active and passive ground pressures due to plate movements on the earth were carried out by Okabe and Mononobe-Matsuo in 1926 and 1929.

What Should Be Considered When Building a Retaining Wall?

When starting the preliminary sizing and design of retaining walls;

- Soil Survey work

- Suitable wall geometry model

- Retaining wall height

- If groundwater is available, the design should be made considering the addition of drainage pipes.

After the design and calculations are made, application follow-up should be done carefully in order to prevent workmanship defects that may arise during application.

What are the Retaining Wall Types?

Retaining walls are divided into three types: flexible, rigid and masonry.

Flexible Retaining Walls

- Rock Filled Retaining Wall,

- Gabion (Wire Mesh or Crate) Retaining Wall,

- Cage Type Retaining Wall,

- Reinforced Soil Retaining Wall,

- There are 5 earthenware retaining walls.

Rigid Retaining Walls

- Weight (Solid) Retaining Wall,

- Reinforced Concrete Retaining Wall,

- Reinforced Concrete Ribbed Retaining Wall,

- There are 4 Prefabricated Retaining Structures.

Masonry Retaining Walls

Masonry retaining walls are walls made of stone and other masonry materials.

- Stone Retaining Wall

- Wooden (log) Retaining Wall

Wall Types in Details

We have specifically discussed flexible, rigid and masonry retaining walls in detail.

Rock Filled Retaining Wall

Rock fill walls are made by piling up large pieces of rock. They ensure the stability of the slopes that move according to the condition of the heel area.

Gabion Retaining Wall

Gabion walls, which are frequently used in architectural garden designs, can also serve as retaining walls when used in larger ways. Stones, gravel, etc. filled into steel cages. These are walls created with materials.

Cage Retaining Walls

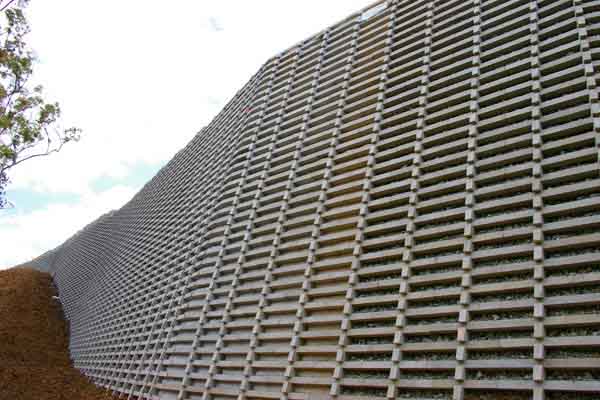

Cage retaining walls are highly flexible against lateral and vertical impacts. Although they generally serve to stabilize slopes and slopes, lattice retaining walls completed with galvanized sheet steel, concrete and wooden coatings have not gained a foothold in our country.

Lattice retaining walls have become an economical way for contractor companies, as they can be manufactured quickly. It is formed as a result of filling gravel and burnt rubble within the cage walls created by the piecemeal celling method. In order to explain the effect of the cellularization technique, we can give an example of the opening of this wall up to 4 m without any damage as a result of the impact.

Reinforced Retaining Walls

Reinforced earth retaining walls; Reinforced earth systems, also known as reinforced earth systems, which we are used to seeing in our country compared to other wall systems and have gained a place especially on highways in recent years, are retaining walls made using geosynthetic cover (felt) in addition to classical reinforcement or fiber reinforcement. It is anchored to the ground by means of galvanized strips applied with anchors between the fillers, parallel to the same direction as the filler. The manufacturing process is completed by using structural elements in the form of geoblocks or keystones as the covering (front surface) material for reinforced earthenware retaining walls.

In order to create sufficient ground friction in the anchored reinforcement, the strips must have a width of 80% to 120% of the wall height. In order to obtain the desired minimum friction, the filling material used must have a minimum internal friction angle of 25° and 25% of it must pass through the sieve no. 200.

Weight (Solid / Natural) Retaining Walls

It is a type of retaining wall that has been frequently used in our country from past years to the present. Massive retaining walls provide the expected friction on the ground with their own weight. Since the stone’s resistance to tensile force is low, the wall must be limited to a certain height. After 4-5 meters, gravity retaining walls pose a risk for the environment.

Reinforced Concrete Retaining Walls

Reinforced concrete retaining walls are 7 to 8 m in L, reverse L or T shape, depending on the solution needed on the land. These are retaining walls that can be manufactured economically up to a height. If walls with dimensions higher than 7 to 8 m are to be created, a mitigation console should be built to reduce the increasing horizontal load and moment occurring on the body.

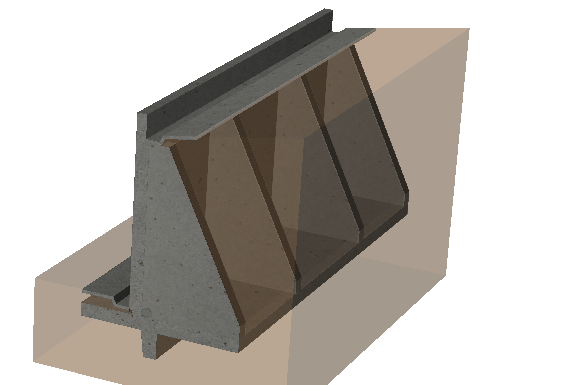

Reinforced Concrete Ribbed Retaining Walls

Reinforced concrete walls provide economical solutions up to 7-8 m in size, but if the heights increase, they increase the cost as mitigation consoles will need to be made. In this case, when cantilever retaining wall calculations are made, quite large cross-sections are encountered. To maintain the economic advantage, ribbed retaining walls are preferred. The moments occurring at the heel point increase with increasing height. Ribs are made at certain intervals to absorb the incoming moments. Ribs to be made according to the needs of the land can be manufactured in front or behind the retaining wall.

Prefabricated Retaining Walls

Although retaining walls are implemented as a result of various calculations, they may be affected by loads beyond the calculations due to workmanship errors during the manufacturing process. Retaining walls, which are exposed to various loads depending on the ground on which they will be built and their function, must be determined most accurately during the project design phase. The on-site manufacturing process may not be possible due to difficult terrain conditions, lack of vehicle traffic in the region, etc. In this process, the walls prepared in factories are taken to the site and the construction is completed.